-

Produkter

- Laboratorieinstrumenter

-

Målere og elektroder til laboratoriebrug

Sension+ metre og prober Kalibreringsstandarder

- Kemikalier, reagenser og standarder

-

Online Analysers

EZ Series Analysers

- Iron

- Aluminium

- Manganese

- Phosphate

- Chloride

- Cyanide

- Fluoride

- Sulphate

- Sulphide

- Arsenic

- Chromium

- Copper

- Nickel

- Zinc

- Ammonium

- Total Nitrogen

- Total Phosphorus

- Phenol

- Volatile Fatty Acids

- Alkalinity

- ATP

- Hardness

- Toxicity

- Sample Preconditioning

- Boron

- Colour

- Nitrate

- Nitrite

- Silica

- Hydrogen Peroxide

- EZ Series Reagents

- EZ Series Accessories

- EZ sc Series Inorganics

- EZ sc Series Metals

- EZ sc Series Nutrients

-

Onlinesensorer og -kontrolenheder

Digitale kontrolenheder (transmittere) Kontrolenheder (analog)

- SC4500

- Orbisphere 366x Ex

- Orbisphere 410/510 Carbon Dioxide

- Orbisphere 410/510 Oxygen

- Orbisphere 410/510 Ozone

pH og ORP sensorer- 1200-S Redox

- 1200-S pH

- 12mm pH/Redox

- 8362 sc High Purity

- Digitale Differentiale Redox

- Digitale Differentiale pH

- Automatiserede laboratoriesystemer

- Claros Water Intelligence System

- Prøveudtagning

-

Laboratorieudstyr og forsyninger

Apparater

- Børster

- Clamps, Rings & Stands

- Crucibles

- Crucibles & Casseroles

- Dispensers & Droppers

- Grab Samplers

- Oil and Grease

- Pipet Aids

- Pipetter

- Slanger

- Stir Bars

- Strativer

- Weighing Accessories

- Øvrige apparater

Generelle laboratorieforbrugsvarer Glas-/plastvarerInstrumenter -

Mikrobiologi

Dehydrerede medier Forberedte medierInstrumenter Labware

- Testsæt og -strips

- Electrochemistry

- PARAMETRE

-

Softwareløsninger

-

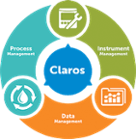

Claros Water Intelligence System

Product Pillars Process Management

- Løsninger til:

- BOD/COD fjernelse

- Nitrifikation/denitrifikation

- Fosforudledning

- Slamstyring

Data Management- Løsninger til:

- Dataopsamling

- Visualisering og analyse

- Rapportering

- Datanøjagtighed

Instrument Management- SLøsninger til:

- Vedligeholdelse

- Fejlfinding

- Fjernadgang

- Laboratorie- og processammenligning

-

Claros Water Intelligence System

- Industrier

- Service

- Nyheder og Events

Orbisphere 3650/113 Portable Analyser, Gaseous or Dissolved Oxygen (O₂), units: % (gaseous) or ppm (liquid)

Produktnr.:

3650/113

Stykpris

Kontakt os

Ideal for Harsh Environments

The Orbisphere 3650 offers a robust portable system solution for oxygen measurement. The compact stainless steel construction is designed for the harsh environment of breweries, but it is also perfectly adapted for laboratory or verification purposes in other beverage applications. In addition, the 3650 can be used across a wide range of applications in the power generation, electronics and life sciences industries.

Designed for use with the Orbisphere GA2400/GA2800 high quality oxygen sensor, these instruments provide fast, accurate and repeatable measurements in both the dissolved and gaseous phase, at line or in the laboratory. For low level applications, the specially configured Orbisphere 3655 measures to 0.1 ppb oxygen.

Simple Operation and Data Management

The Orbisphere 3650 inlet tube is connected to a sample point or to a piercing device by a simple connector, making it quick and easy to install. The sample flows over the sensor membrane in the flow chamber, with an output valve controlling the sample's flow rate.

Each instrument comes with a Windows software package that enables the user to analyse up to 500 stored measurements and to configure the instrument. Using the RS232 connection, stored measurements can be simply downloaded to a PC for analysis.

No sample preparation necessary

The use of the Orbisphere GA2400/GA2800 sensor with this portable instrument allows for very quick cleaning with nothing more than tap water and requires no technical skills. The sensor refurbishment (typically every 6 months) takes only 3 minutes with a pre-mounted membrane cartridge and electrolyte, eliminating any risk of incorrect membrane positioning.

The Orbisphere 3650 uses two C-type, NiMH or alkaline batteries. Changing the batteries is quick and easy; stored measurements are not lost if batteries go flat or are being changed.

Measures gas in dissolved and gaseous phase

Calibration after each sensor refurbishment is recommended. A traceable and simple calibration can be done directly in air by measuring its oxygen content with the use of the built-in pressure sensor and the automatic software calculation. Alternatively, the calibration can be performed against a liquid or gaseous sample of known concentration by simply entering the gas concentration via the keyboard.

Specifikationer

Batteri levetid:

40 hours continuous use

Certificeringer:

CE: EN61010-1: LVD Directive

ISO9001/EN29001

ISO9001/EN29001

Datalagring:

500 data

Dimensioner (H x B x D):

150 mm x 115 mm x 220 mm

Display opløsning:

0.001 ppm or 0.001%

Garanti:

24 måneder

Kapslingsklasse:

IP65 / NEMA4

Model:

3650/113

Omgivelsestemperatur:

-5 °C - 100 °C (23 °F - 212 °F)

Parameter:

Oxygen, gaseous or dissolved

Phase Type:

Combined liquid and gas phase

Prøvetemperatur:

-5 °C - 60 °C (23 °F - 140 °F)

Strømforsyning:

Two C-type cells, NiCd or alkaline, each 26 x 50 mm, 2.4 - 3 Volt total

Temperaturkompensation:

-5 °C - 60 °C (23 °F - 140 °F)

Tryk:

Max. 10 bar (145 psi)

Vægt:

2.4 kg